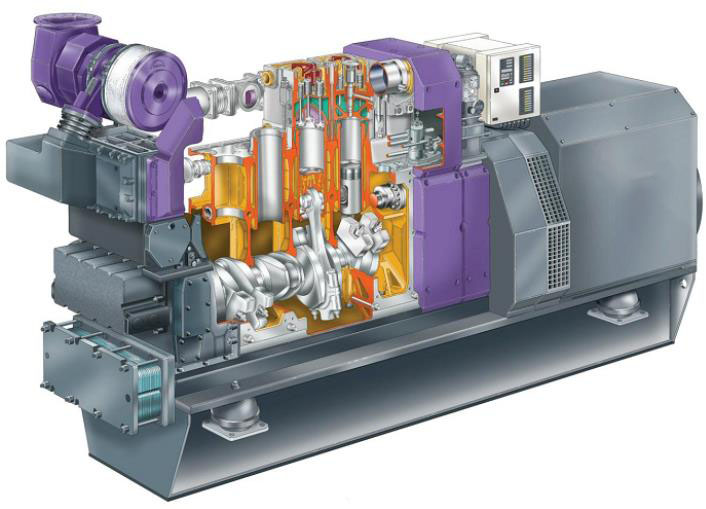

MAN B&W 8L 16/24 Crankshaft

We offer MAN B&W Engine Crankshaft,

MAN B&W 8L 16/24 Diesel Engine Crankshaft

5L 16/24, 6L 16/24, 7L 16/24

Crankshaft is in good condition STD size, all following tests done

Measurment Control

Hardness Control

Crack Test

Bending

For more information please contact with us.

Ask Decho Marine for quotations when you need marine diesel engines Crankshaft or major spare parts for MAN B&W 5L 16/24, 6L 16/24, 7L 16/24 Diesel Engines andGenerators

MAN B&W Crankshaft

A single-cylinder diesel engine is a type of internal combustion engine that has only one cylinder. It is commonly used in small applications such as generators, water pumps, and agricultural machinery. Since the engine has only one cylinder, the crankshaft needs to be designed carefully to handle all the power generated by the engine.

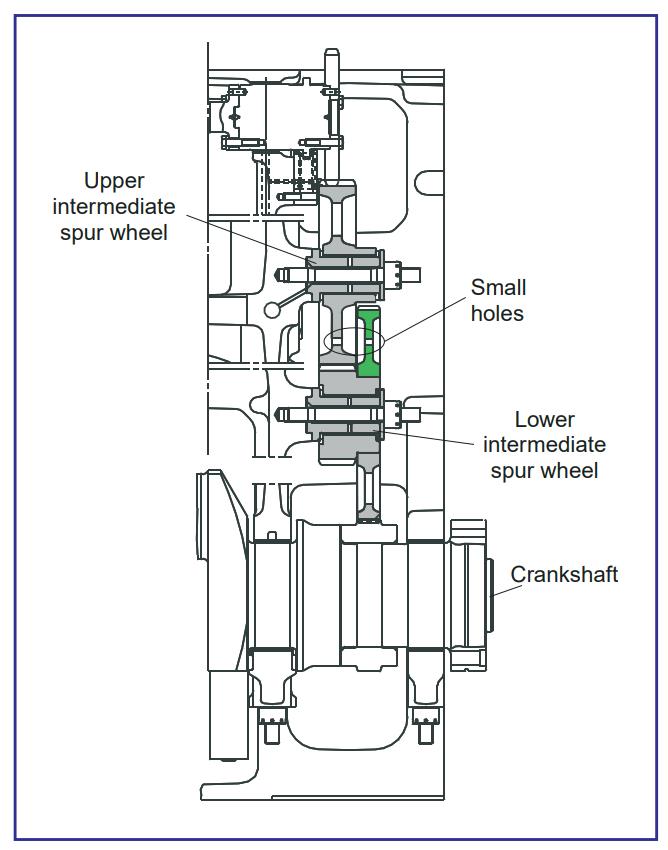

Assembly of gear wheels for valve camshaft and Injection valve camshaft, without

mounted flywheel

Following description is for mounting the gearwheels

in the control drive when alternator, flywheel and cover

on coupling side are dismantled from the engine.

Mounting of intermediate gearwheels

1) Turn the crankshaft to top dead centre for the

last cylinder (the cylinder nearest to the coupling

side).

2) Mount the upper intermediate gearwheel.

3) Mount the lower intermediate gearwheel so the

marks on the lower intermediate gearwheel are

corresponding with the mark on the crankshaft

gearwheel, see fig 1(E2). At the same time turn

the upper intermediate gearwheel so that the

small holes in the circumference of the two

intermediate gearwheels are corresponding,

see fig 2.

Note: The punch mark on the crankshaft gearwheel

is placed on the 13 teeth counting counter clockwise

from the joint of the gearwheel, see fig 3.

Design of Crankshaft for Single Cylinder Diesel Engine

The design of a crankshaft for a single-cylinder diesel engine is critical to ensure that it can withstand the forces generated by the combustion process. The design should take into consideration the following factors:

Stroke length

The stroke length of the piston determines the length of the crankshaft. The longer the stroke, the longer the crankshaft needs to be.

Material selection

The material selection for the crankshaft is crucial to ensure that it can withstand the forces generated by the engine. Common materials used for single-cylinder diesel engine crankshafts include forged steel, cast iron, and ductile iron.

Counterweights

Counterweights are added to the crankshaft to balance the rotating assembly and reduce vibrations. In a single-cylinder engine, counterweights are particularly important to minimize the effects of the combustion forces.

Fillet radius

The fillet radius is the curved portion between the crankpin and the crank arm. A larger fillet radius can help to reduce stress concentrations and improve the fatigue life of the crankshaft.

FAQs

- What is a single-cylinder diesel engine? A single-cylinder diesel engine is a type of internal combustion engine that has only one cylinder.

- What is the role of the crankshaft in a single-cylinder diesel engine? The crankshaft converts the reciprocating motion of the piston into rotational motion that can drive a load.

- What materials are used to make crankshafts for single-cylinder diesel engines? Common materials used for single-cylinder diesel engine crankshafts include forged steel, cast iron, and ductile iron.

- Why are counter