Cylinder Liner

The Cylinder Liner and its Parts:

The cylinder liner is a critical component of the main engine in two-stroke diesel engines. We offer MAN B&W, WARTSILA, and UEC brands. For engines such as the S35MC, S42MC, S46MC-C, S50MC-C, and S60ME-C, the following parts are required to install a cylinder liner:

- Water guide jacket (part number: 90302-184-10)

- Screw (part number: 90302-184-105)

- O-ring (part number: 90302-184-117) – made of FPM material

- O-ring (part number: 90302-184-129)

- Stud (part number: 90302-184-142)

- Nut (part number: 90302-184-154)

- Cooling water connection (part number: 90302-184-166)

- Gasket (part number: 90302-184-178)

- O-ring (part number: 90302-184-201)

- Cooling water pipe (part number: 90302-184-213)

- Gasket (part number: 90302-184-22)

- Screw (part number: 90302-184-225)

- Piston cleaning ring (part number: 90302-184-34)

- Cylinder liner (part number: 90302-184-46; alternate part number: 3170262-7)

- Packing ring (part number: 90302-184-58)

- Plug screw (part number: 90302-184-71)

- Clamp (part number: 90302-184-95)

As the heart of any engine, the cylinder plays a vital role in the performance and longevity of the engine. To ensure optimal performance and efficiency, the cylinder needs to be protected from wear and tear. This is where the diesel engine cylinder liner comes in.

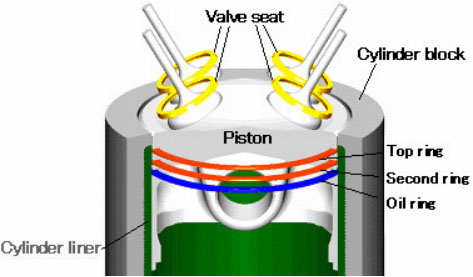

A diesel engine cylinder liner, also known as a cylinder sleeve, is a cylindrical part that is fitted into an engine block to form a cylinder. The liner acts as the inner wall of the cylinder and forms a sliding surface for the piston rings while retaining the lubricant within. It is one of the most important functional parts that make up the interior of an engine. In this article, we will explore everything you need to know about diesel engine cylinder liners.

Heat Transfer

One of the main functions of the diesel engine cylinder liner is heat transfer. The liner needs to transfer heat from the combustion process to the engine coolant quickly and efficiently. This is important to prevent overheating and ensure that the engine operates within the required temperature range.

The cylinder liner’s excellent sliding surface characteristics ensure that the heat transfer process is efficient. It is important to use high-quality standard liners with a certificate to ensure optimal heat transfer.

Material for Cylinder Liner

Cylinder liners are commonly made from Inconel or Nichrome iron. The Nichrome iron used includes 3.5% carbon, 0.6% manganese, 1.5% phosphorus, 0.05% sulfur, 2% silicone, 2% nickel, and 0.7% chromium. Inconel is a high-performance material that is resistant to wear, corrosion, and high-temperature environments.

Heat Treatment

To improve wear resistance, the diesel engine cylinder liner is hardened by heating it to 855°C-865°C for 30 to 40 minutes and then quenched in oil. This type of heat treatment increases the liner’s life by a factor of three compared to grey cast iron or cast iron cylinders.

Advantages of Cylinder Liners

There are several advantages to using diesel engine cylinder liners, including:

- They protect the engine block from wear and tear.

- They allow for easier maintenance and repair of the engine.

- They provide a tight seal for the piston rings, preventing blow-by.

- They reduce friction between the piston rings and the cylinder wall, improving engine efficiency and performance.

- They improve heat transfer between the cylinder and coolant, preventing engine overheating.

Frequently Asked Questions

Q: What is the difference between a cylinder liner and a piston sleeve? A: A cylinder liner is a cylindrical part that is fitted into an engine block to form a cylinder. A piston sleeve, on the other hand, is a cylindrical part that is fitted onto the piston. The piston sleeve helps to protect the piston from wear and tear.

Q: How often should I replace the cylinder liner? A: The lifespan of a diesel engine cylinder liner depends on several factors, including the engine’s design, operating conditions, and maintenance. Generally, cylinder liners can last for several years before needing replacement.

Q: Can I replace the cylinder liner myself? A: It is recommended to have a professional mechanic replace the cylinder liner. Replacing the cylinder liner requires specialized tools and knowledge.

Conclusion

The diesel engine cylinder liner plays a crucial role in protecting the engine block from wear and tear, improving engine efficiency and performance, and preventing engine overheating. By using high-quality cylinder liners and ensuring proper maintenance, you can ensure optimal engine performance and longevity.