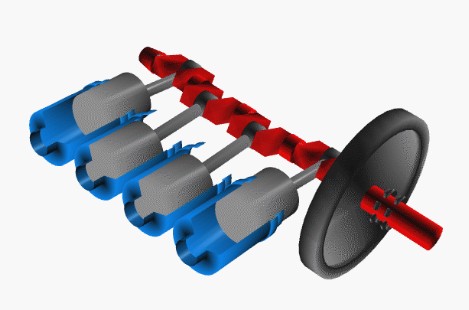

7L 16/24 Diesel Engine Crankshaft

Diesel crankshafts are designed to withstand high stresses and loads generated by the engine. The design of a crankshaft depends on the application, size, and power of the engine. Typically, a crankshaft consists of one or more throws, which are offset from each other by a certain angle. The throws are connected to the crankpins, which are then connected to the connecting rods.

L16/24 Diesel Engine Spare Part No.

| PART DESCRIPTION | PART NO. |

|---|---|

| MAN B&W L 16-24 Crankshaft | 51001-03H |

| MAN B&W L 16-24 Crankhaft | 51001-03H-021 |

| MAN B&W L 16-24 Crankhaft | 51001-03H-033 |

| MAN B&W L 16-24 Crankhaft | 51001-03H-045 |

| MAN B&W L 16-24 Crankhaft | 51001-03H-057 |

| MAN B&W L 16-24 Crankhaft | 51001-03H-069 |

| MAN B&W L 16-24 Cylindrical Pin | 51001-03H-070 |

| MAN B&W L 16-24 Nut | 51001-03H-082 |

| MAN B&W L 16-24 Bolt | 51001-03H-094 |

| MAN B&W L 16-24 Counterweight | 51001-03H-104 |

| MAN B&W L 16-24 Plug Screw | 51001-03H-116 |

| MAN B&W L 16-24 Plug Screw | 51001-03H-128 |

| MAN B&W L 16-24 Screw | 51001-03H-141 |

| MAN B&W L 16-24 O-Ring | 51001-03H-153 |

| MAN B&W L 16-24 Cylindrical Pin | 51001-03H-165 |

| MAN B&W L 16-24 Cylindrical Pin | 51001-03H-177 |

| MAN B&W L 16-24 Screw | 51001-03H-189 |

| MAN B&W L 16-24 Gearwheel 2/2 | 51001-03H-190 |

| MAN B&W L 16-24 Cylindrical Pin | 51001-03H-200 |

Design of Diesel Crankshafts:

The design of the crankshaft is critical in determining the performance and durability of the engine. The shape and size of the throws and crankpins, the fillet radius, and the material properties all play a vital role in the design of the crankshaft. Modern crankshafts are designed using advanced computer simulations and modeling techniques to ensure optimal performance and longevity.

Materials Used in Diesel Crankshafts:

Diesel crankshafts are typically made of forged steel or cast iron. Forged steel crankshafts are stronger and more durable than cast iron crankshafts, but they are also more expensive. Cast iron crankshafts are less expensive but are not as strong as forged steel crankshafts.

The material properties of the crankshaft are critical in determining its performance and durability. The material must have high strength, fatigue resistance, and wear resistance to withstand the high stresses and loads generated by the engine.

Manufacturing Process of Diesel Crankshafts:

The manufacturing process of diesel crankshafts involves several steps, including forging, machining, heat treatment, and finishing. Forged steel crankshafts are made by heating a billet of steel to a high temperature and then shaping it using a forging press or hammer. The forged crankshaft is then machined to the required dimensions and tolerances.

Cast iron crankshafts are made by pouring molten iron into a sand mold. The casting is then cooled and removed from the mold. The cast crankshaft is then machined to the required dimensions and tolerances.

Heat treatment is an essential step in the manufacturing process of diesel crankshafts. Heat treatment involves heating the crankshaft to a high temperature and then quenching it in oil or water. This process improves the strength and durability of the crankshaft by hardening the surface and creating a compressive residual stress layer.

Applications of Diesel Crankshafts:

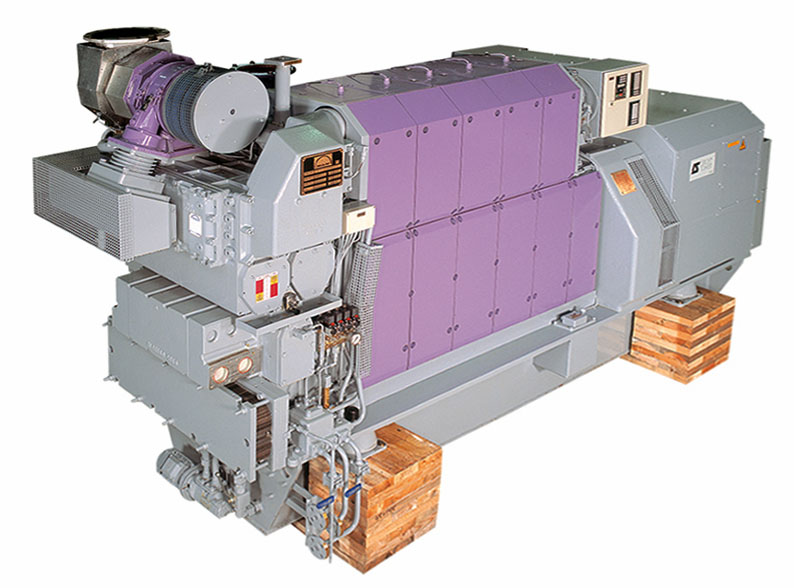

Diesel crankshafts are used in a wide range of applications, including marine propulsion, power generation, and heavy equipment. They are also used in automotive and truck engines. Diesel engines are known for their high torque output and fuel efficiency, making them ideal for heavy-duty applications.

MAN B&W (Kawasaki, Mitsui, STX, Hyundai, Hudong, Doosan, HSD, Hitachi, Ssangyong)

8L16/24, 7L16/24, 6L16/24