Wet Cylinder Liners in Two-Stroke Diesel Engines: Everything You Need to Know

What are Wet Cylinder Liners?

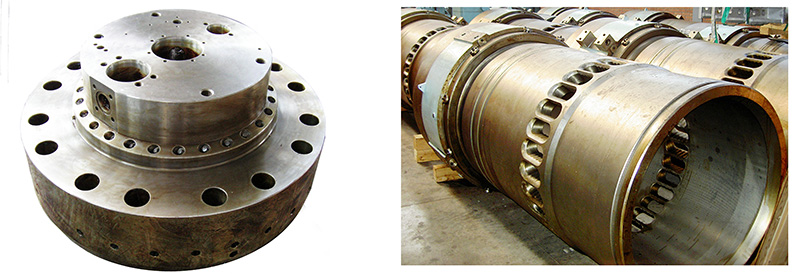

Wet cylinder liners are a type of cylinder liner that is used in two-stroke diesel engines. They are called “wet” because they are in direct contact with the engine’s coolant, which cools them down during operation. Wet cylinder liners are usually made from cast iron or steel and are installed inside the engine block. They are designed to provide a smooth and durable surface for the piston to travel on and to ensure that the engine runs smoothly and efficiently.

Advantages of Wet Cylinder Liners

One of the main advantages of wet cylinder liners is their ability to dissipate heat quickly. This is because the coolant that surrounds them absorbs the heat generated by the combustion process. Wet cylinder liners also help to reduce engine wear and tear by providing a smooth surface for the piston to travel on. This reduces friction and minimizes the risk of damage to the engine’s components.

Another advantage of wet cylinder liners is that they are relatively easy to replace. Because they are installed inside the engine block, they can be removed and replaced without having to disassemble the entire engine. This makes maintenance and repair work easier and less time-consuming.

Types of Wet Cylinder Liners

There are two main types of wet cylinder liners: closed-end and open-end. Closed-end wet cylinder liners are sealed at the bottom, while open-end wet cylinder liners are open at both ends. Closed-end wet cylinder liners are typically used in larger engines, while open-end wet cylinder liners are used in smaller engines.

Closed-end wet cylinder liners are more durable and offer better protection against corrosion. They are also more expensive than open-end wet cylinder liners. Open-end wet cylinder liners, on the other hand, are easier to install and replace. They are also less expensive than closed-end wet cylinder liners.

Maintenance of Wet Cylinder Liners

Proper maintenance of wet cylinder liners is essential to ensure that they function properly and last a long time. This involves regularly checking the coolant level and quality, as well as checking for any signs of corrosion or damage to the liners themselves.

If the coolant level is low, it should be topped up immediately. If the coolant quality is poor, it should be replaced. Corrosion or damage to the liners should be addressed as soon as possible to prevent further damage to the engine. In conclusion, wet cylinder liners are an essential component of two-stroke diesel engines. They provide a smooth and durable surface for the piston to travel on and help to dissipate heat quickly. Proper maintenance is essential to ensure that they function properly and last a long time. We hope that this article has provided you with valuable information about wet cylinder liners and their importance in two-stroke diesel engines.