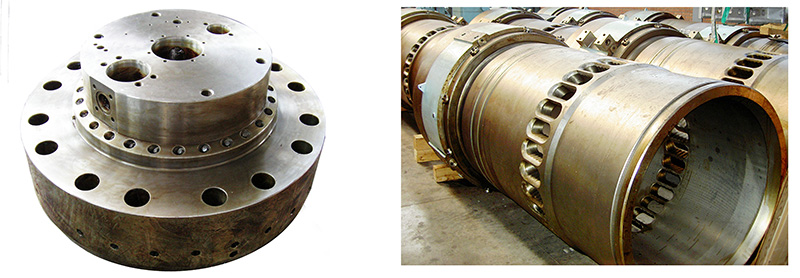

Cylinder Liner Parts for MAN B&W, WARTSILA, and UEC Two-Stroke Diesel Engines

Cylinder liners are crucial components of the main engine in MAN B&W, Wartsila, and UEC two-stroke diesel engines. They ensure the proper functioning of the engine by providing a high-strength, wear-resistant surface for the piston to move against. The cylinder liners for the S35MC, S42MC, S46MC-C, S50MC-C, and S60ME-C engines are identified by the part number 90302-184. In this article, we will discuss the importance of cylinder liners and their associated components, and how they play a critical role in ensuring the proper functioning of diesel engines.

The Cylinder Liner and its Parts

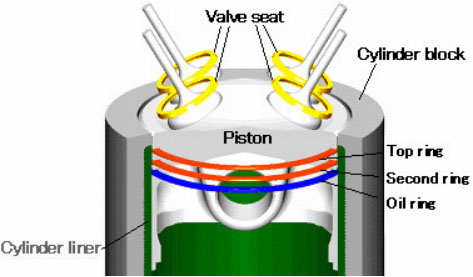

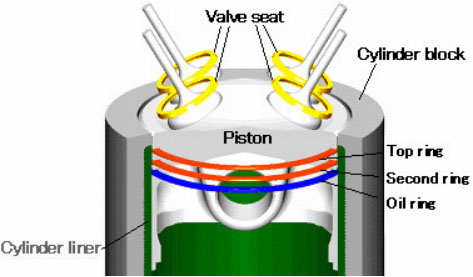

The cylinder liner is a cylindrical part that is inserted into the engine block, and provides a high-strength, wear-resistant surface for the piston to move against. The cylinder liner is made of cast iron, and is designed to withstand the high pressures and temperatures of the combustion process. The cylinder liner has several parts that are necessary for its proper functioning, including the water guide jacket, screw, o-rings, stud, nut, cooling water connection, gaskets, cooling water pipe, piston cleaning ring, packing ring, plug screw, and clamp.

The water guide jacket

The water guide jacket is an essential component of the cylinder liner, as it helps to control the flow of cooling water through the liner. This is important, as the liner can get extremely hot during the combustion process, and the water jacket helps to regulate the temperature of the liner. The o-rings and gaskets are also critical components of the cylinder liner, as they provide a seal between the liner and other engine components. This helps to prevent leaks, which can be detrimental to the engine’s performance.

The stud and nut are used to secure the cylinder liner in place, and the cooling water connection and pipe provide the necessary water flow to maintain proper engine temperature. The piston cleaning ring helps to remove any debris that may accumulate on the piston surface, which can cause damage to the engine if left unchecked. The packing ring provides a seal between the piston and cylinder liner, which is important for maintaining proper compression and preventing leaks.

The Importance of High-Quality Construction and Materials

The cylinder liner and its associated components play a critical role in ensuring the proper functioning of diesel engines. As such, it is essential that they are made of high-quality materials and constructed to exacting standards. The cylinder liner must be able to withstand high pressures and temperatures, as well as resist wear and corrosion over time. The water jacket must be designed to efficiently control the flow of cooling water, and the o-rings and gaskets must be made of materials that are resistant to heat and chemicals.

The stud, nut, and cooling water connection must also be made of high-strength materials that are resistant to corrosion, as they are exposed to the harsh environment of the engine. The piston cleaning ring must be able to effectively remove debris from the piston surface, while the packing ring must be made of materials that are able to withstand the high temperatures and pressures of the combustion process. Overall, the high-quality construction and materials used in the manufacture of cylinder liners and their associated components help to ensure long-term reliability and durability.

Conclusion

In conclusion, cylinder liners and their associated components play a critical role in ensuring the proper functioning of diesel engines. The cylinder liner provides a high-strength, wear-resistant surface for the piston to move against, while the water jacket, o-rings, gaskets, stud, nut, cooling water connection, cooling water pipe, piston cleaning ring, packing ring, plug screw, and clamp work together to maintain proper engine temperature, compression, and prevent leaks. The high-quality construction and materials used in the manufacture of these components help to ensure long-term reliability and durability, which is essential for Cylinder liners are one of the most crucial components of the main engine in MAN B&W, Wartsila, and UEC two-stroke diesel engines. They are responsible for providing a high-strength, wear-resistant surface for the piston to move against, ensuring the proper functioning of the engine. Among the MAN B&W and Wartsila engines, cylinder liners for the S35MC, S42MC, S46MC-C, S50MC-C, and S60ME-C engines are identified by the part number 90302-184.

The cylinder liner itself is typically made of cast iron or steel and is designed to withstand the high-temperature and high-pressure environment inside the engine. It must be able to handle the constant friction and wear caused by the piston’s movement and maintain its shape and dimensions over a long period of time.