Importance of Proper Cylinder Liner Installation for Maximum Diesel Engine Performance

Diesel engines are powerful machines that are used in a variety of applications, from heavy-duty trucks to generators, ships, and even locomotives. They are known for their reliability, durability, and fuel efficiency, making them a popular choice in many industries. However, to ensure optimal performance, it is essential to install the cylinder liner correctly. In this article, we will discuss the importance of proper cylinder liner installation and how it can help maximize diesel engine performance.

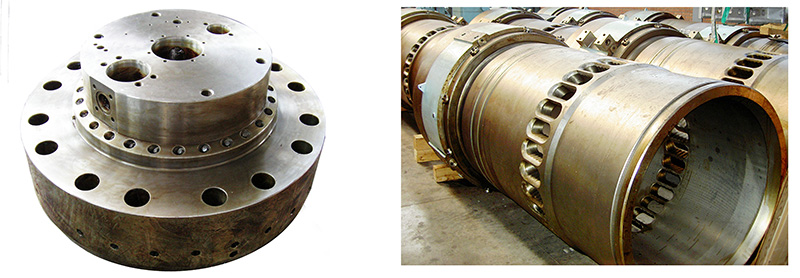

What is a Cylinder Liner?

A cylinder liner, also known as a cylinder sleeve, is a cylindrical component that is installed inside the engine block to provide a smooth and wear-resistant surface for the piston to move up and down. It also helps to seal the combustion chamber and prevent coolant and oil from entering. Cylinder liners are typically made of cast iron, although some modern engines use aluminum or other materials.

Why is Proper Cylinder Liner Installation Important?

Proper cylinder liner installation is crucial to ensure optimal engine performance and longevity. If the liner is not installed correctly, it can lead to several problems, such as:

- Reduced Compression: The cylinder liner must be installed with the correct bore size and height to ensure the proper compression ratio. If the liner is too loose or too tight, it can cause a reduction in compression, which can result in lower power output, decreased fuel efficiency, and increased emissions.

- Excessive Wear: If the liner is not installed correctly, it can cause uneven wear on the piston rings, resulting in increased oil consumption, loss of power, and premature engine failure.

- Overheating: A poorly installed liner can cause hot spots in the combustion chamber, leading to overheating, which can damage the engine components and cause permanent damage.

- Leaks: Improper installation can result in coolant or oil leaks, which can cause engine damage and lead to costly repairs.

How to Install Cylinder Liners Properly

Proper cylinder liner installation involves several critical steps, including:

- Preparation: Before installation, the engine block must be thoroughly cleaned and inspected for any damage or cracks. The liner should also be inspected for any defects or damage.

- Size and Fit: The liner must be the correct size and fit for the engine block. The bore size and height should be measured to ensure the proper fit and compression ratio.

- Lubrication: The liner should be lubricated with a suitable lubricant before installation to prevent damage to the engine components.

- Installation: The liner should be carefully lowered into the cylinder bore using a liner installation tool. The liner should be tapped gently into place until it is flush with the engine block.

- Final Check: Once the liner is installed, it should be checked for proper fit and alignment. The piston should move smoothly up and down, and there should be no leaks or signs of damage.

In conclusion, proper cylinder liner installation is crucial for maximizing diesel engine performance and longevity. It is a complex process that requires attention to detail and precision. A poorly installed liner can cause several problems that can lead to decreased power output, increased fuel consumption, and costly repairs. Therefore, it is essential to hire a professional mechanic or technician with the necessary skills and experience to perform the job correctly.