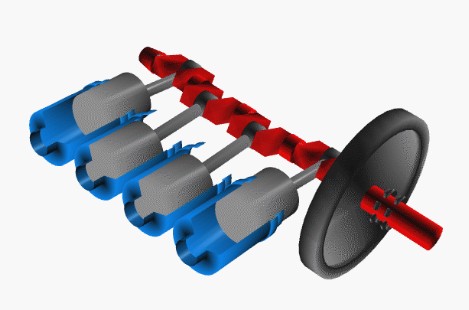

MAN B&W 5L 21/31 Crankshaft

5L 21/31 Marine Crankshaft

The crankshaft of a marine engine converts the piston’s reciprocating motion to rotational motion. A connecting rod connects the piston to the crankshaft and transmits the reciprocating motion. Different engines complete a power cycle at varying crankshaft revolutions. For instance, a 2-stroke engine completes one power cycle per revolution, while a 4-stroke engine completes one power cycle per two revolutions.

How crankshaft works

The diesel engine’s crankshaft operates the crank mechanism, consisting of a crankpin and a crank that is connected to the connecting rod. To reduce the thrust on the crank, the crankshaft is equipped with a shock absorber. The crankshaft is also equipped with a counterweight to reduce bending loads.

The four-stroke engine’s crankshaft operates as follows:

- During the downstroke, when the engine piston moves from TDC to BDC, it transmits its motion to the crankshaft through the connecting rod.

- The crank then converts the piston’s linear motion into rotational motion and transmits it to the camshaft.

- The rotational motion of the camshaft opens the intake valve, allowing the air-fuel mixture to enter the combustion chamber.

- As the air-fuel mixture fills the combustion chamber, the piston moves up from BDC to TDC and compresses the mixture. During this process, both the intake and exhaust valves are closed by the camshaft. As the compression process is complete, the first rotation of the crankshaft is complete.

- At the end of the compression process, the ignition process occurs.

- The ignition process releases heat from the compressed mixture, forcing the piston to move downward. This stroke is known as the power stroke. As the piston moves down, it transmits its reciprocating motion to the connecting rod, which in turn transmits it to the crankshaft.

- One end of the crank is connected to the flywheel. When the crank receives the movement of the piston, it transmits this movement to the flywheel. The flywheel stores this movement and further drives the wheels of the vehicle.

- After the power stroke, the engine piston moves further down to expel the exhaust gas. During this process, the camshaft receives the movement of the piston through the crank and opens the exhaust valve, while the intake valve remains closed. The piston pushes the exhaust gas out of the combustion chamber.

MAN L21-31 slow-speed propulsion engines features:

- They have a more ideal power matching, providing the most suitable shaft speed for propeller selection;

- They have good economy and can achieve the minimum daily fuel consumption;

- They have high reliability and increased TBO (time between overhauls);

- They have a compact design and reduced size and weight;

- They have fewer components, making them easy to manufacture, install, and maintain, and reducing costs;

- They are easy to operate, maintain, and service;

- They comply with new exhaust gas emission regulations.

Why Choose Decho-Marine Services?

Decho-Marine Services is a leading supplier of marine engine maintenance and repair services, specializing in MAN slow-speed propulsion engines. We offer a wide range of services, including:

- Regular maintenance and inspections

- Repairs and overhauls

- Spare parts sourcing and replacement

- Emergency response services

Our team of experienced professionals is dedicated to providing reliable and efficient services that ensure your vessel operates at peak performance. We understand the importance of minimizing downtime and maximizing performance, which is why we work closely with our clients to develop customized maintenance plans that meet their unique needs.

When you choose Decho-Marine Services, you can trust that you’re getting high-quality services from a trusted supplier. Contact us today to learn more about our services and how we can help you keep your vessel running smoothly.