MAN 7S35MC-MK7 Cylinder Liner

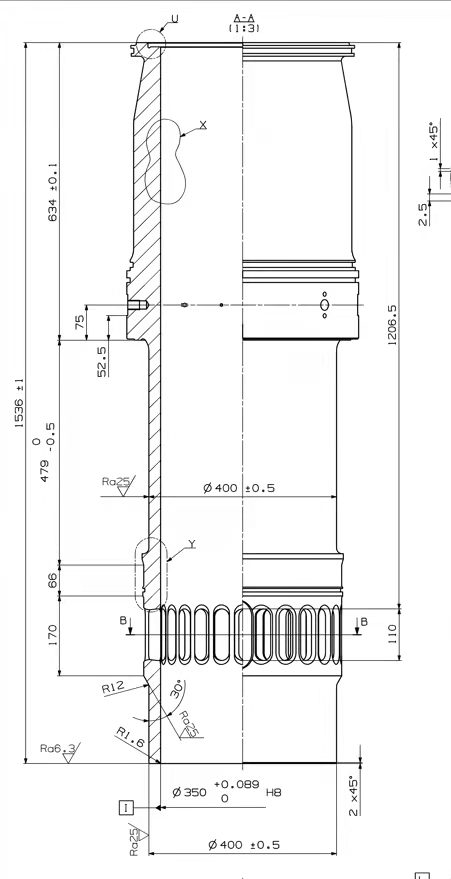

MAN 7S35MC-MK7 Cylinder Liner

The MAN 7S35MC-MK7 engine is one of the most popular engines used in the maritime industry, known for its high efficiency and performance. But, to keep it running smoothly, it’s essential to pay attention to all the engine components, including the cylinder liner. The cylinder liner is an integral part of the engine, and any damage or malfunctioning of the liner can lead to engine failure. In this article, we’ll dive deep into the MAN 7S35MC-MK7 cylinder liner, its function, and how to maintain it.

MAN 7S35MC-MK7 Engine Overview

The MAN 7S35MC-MK7 engine is a two-stroke, turbocharged diesel engine designed for large cargo ships, tankers, and container vessels. It’s a popular choice due to its high power output, low fuel consumption, and reduced emissions. The engine has a bore of 350mm, stroke of 1,660mm, and can generate up to 5,880 kW of power at 173 rpm.

What is a Cylinder Liner?

A cylinder liner is a cylindrical component that fits into the engine block’s cylinder bore. It forms a sliding surface for the piston rings while providing a sealing surface for the combustion chamber. Cylinder liners are made of materials that can withstand high temperature, pressure, and corrosive environments. The primary function of the cylinder liner is to reduce friction and wear between the piston rings and cylinder wall.

Types of Cylinder Liners

There are various types of cylinder liners, including:

Wet Liners

Wet liners are removable cylinder liners that are in direct contact with the coolant. They provide better cooling and heat dissipation and are easier to replace. However, they’re less durable than dry liners.

Dry Liners

Dry liners are non-removable liners that sit directly on the engine block. They’re more durable than wet liners but offer less cooling efficiency.

Mono Block Liners

Mono block liners are made of one piece of cast iron, and they’re directly cast into the engine block. They provide excellent heat transfer and durability, but they’re challenging to replace.

Characteristics of MAN 7S35MC-MK7 Cylinder Liner

The MAN 7S35MC-MK7 cylinder liner is a wet liner made of cast iron with a chrome-plated bore surface. The chrome plating increases the liner’s durability and resistance to wear, corrosion, and scuffing. The liner’s thickness is designed to withstand the high temperatures and pressures within the combustion chamber. It’s also engineered to have sufficient hardness and rigidity to resist deformation caused by piston movement and combustion forces.

Function of Cylinder Liner

The cylinder liner’s primary function is to provide a sliding surface for the piston rings while forming a seal for the combustion chamber. During the engine’s operation, the liner is subjected to extreme heat, pressure, and corrosion. It must maintain its shape, surface finish, and hardness to ensure optimal engine performance. The liner’s ability to reduce friction and wear directly impacts engine efficiency and fuel consumption. A damaged liner can cause a drop in engine power, increased oil consumption, and higher exhaust emissions.

How to Maintain Cylinder Liner

Proper cylinder liner maintenance is crucial to ensure optimal engine performance and longevity. Here are some tips to maintain the MAN 7S35MC-MK7 cylinder liner:

1. Regular Inspection

Regular inspections can detect early signs of wear, corrosion, and damage to the liner. Check for cracks, pitting, and scoring on the liner’s surface. Also, ensure the liner is securely seated in the engine block and has the correct alignment and protrusion.

2. Coolant Quality

The coolant quality can affect the liner’s durability and resistance to corrosion. Use a high-quality coolant and ensure the correct mixture and pH levels. Avoid using seawater as a coolant, as it can cause severe corrosion.

3. Lubrication

Proper lubrication of the piston rings and liner is essential to reduce friction and wear. Use high-quality lubricants recommended by the engine manufacturer and follow the correct lubrication schedule.

4. Proper Operation

The engine’s proper operation can impact the liner’s longevity. Avoid overloading the engine, as it can cause excessive pressure and heat. Also, ensure the engine’s cooling system is functioning correctly to prevent overheating.

Common Cylinder Liner Problems and Solutions

Some common cylinder liner problems include wear, corrosion, and scuffing. Here are some solutions to these problems:

1. Wear

Wear is the most common problem faced by cylinder liners. It can cause a drop in engine power, increased oil consumption, and higher emissions. Solutions include:

- Regular inspection and maintenance to detect early signs of wear

- Use of high-quality lubricants to reduce friction and wear

- Avoid overloading the engine and follow the recommended operating conditions

2. Corrosion

Corrosion can occur due to poor coolant quality, incorrect coolant mixture, or using seawater as a coolant. It can cause pitting and scoring on the liner surface, leading to reduced engine performance. Solutions include:

- Use of high-quality coolant with the correct mixture and pH levels

- Regular inspection and maintenance to detect signs of corrosion

- Avoid using seawater as a coolant

3. Scuffing

Scuffing can occur due to insufficient lubrication or improper engine operation. It can cause severe damage to the liner’s surface, leading to reduced engine performance. Solutions include:

- Proper lubrication of the piston rings and liner

- Avoid overloading the engine and follow the recommended operating conditions

- Use high-quality lubricants to reduce friction and wear