A Comprehensive Guide on Cylinder Liners

Cylinder liners are an essential component of an engine that protects the engine block from wear and tear and dissipates heat from the combustion process. In this article, we will cover everything you need to know about cylinder liners, including their definition, function, types, materials, and manufacturing processes.

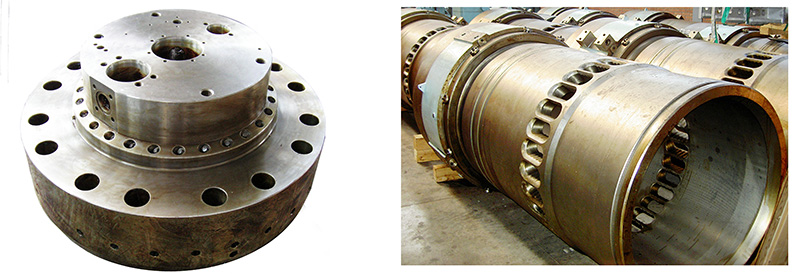

What is a Cylinder Liner?

A cylinder liner, also known as a cylinder sleeve, is a cylindrical component that fits inside the engine block’s cylinder bore. Its primary function is to serve as the inner surface of the cylinder and provide a sliding surface for the piston rings to seal against. Cylinder liners also help dissipate heat from the combustion process and protect the engine block from wear and tear.

Why are Cylinder Liners Important?

Cylinder liners play a crucial role in the performance and longevity of an engine. They protect the engine block from the extreme pressure and heat generated during combustion and help maintain the cylinder bore’s dimensions over time. Cylinder liners also improve the engine’s sealing ability, reduce friction, and contribute to better fuel economy and lower emissions.

Types of Cylinder Liners

There are three main types of cylinder liners: wet, dry, and semi-dry. Wet liners are the most common and are used in most modern engines. They are surrounded by coolant and are in direct contact with the engine’s coolant system. Dry liners are self-contained and do not come into contact with the coolant system, while semi-dry liners are a hybrid of wet and dry liners.

Materials Used for Cylinder Liners

Cylinder liners can be made from a variety of materials, including cast iron, steel, aluminum, and ceramic. Cast iron is the most common material used in cylinder liners due to its durability and excellent heat dissipation properties. Steel and aluminum liners are also used in some high-performance engines. Ceramic liners are relatively new and are still being developed for commercial use.

Manufacturing Processes for Cylinder Liners

Cylinder liners are manufactured using a variety of processes, including centrifugal casting, static casting, and forging. Centrifugal casting is the most common process used in mass production due to its efficiency and ability to produce high-quality liners. Static casting and forging are used for smaller production runs and custom applications.

Conclusion

In conclusion, cylinder liners are an essential component of any engine and play a crucial role in its performance and longevity. Understanding the different types, materials, and manufacturing processes for cylinder liners will help you make informed decisions when it comes to engine maintenance and repair. By following the guidelines set out in this guide, you will have a complete understanding of cylinder liners, their importance, and how they can affect engine performance.